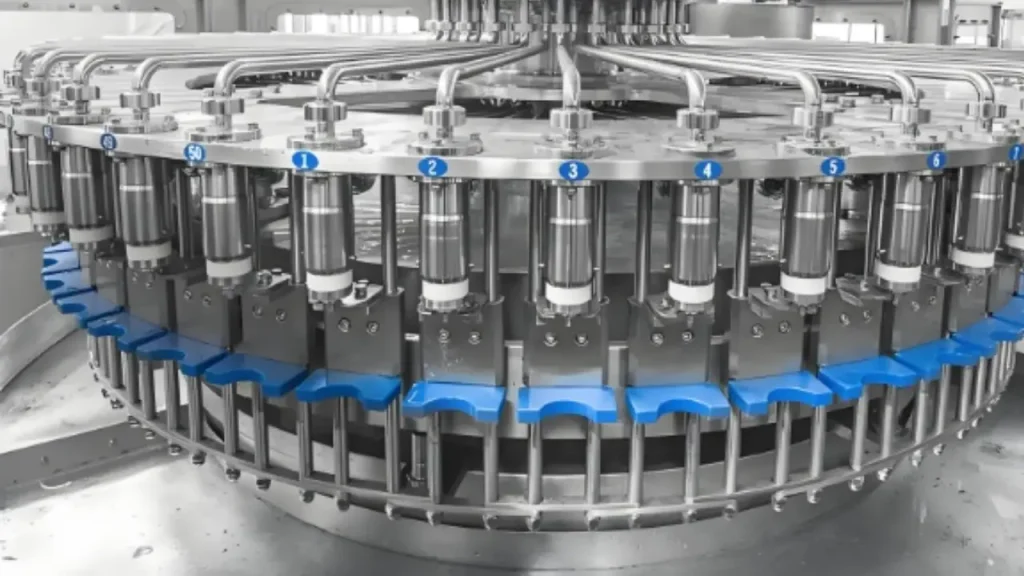

This fully automatic rotary blow molding machine, independently developed by our company using international bottle-making technology, utilizes high-pressure compressed air to blow PET preforms into finished bottles. The entire operation is performed automatically without the need for any manual intervention.

The machine requires preforms that match the specific bottle design being produced. It features a high degree of automation and intelligence, stable and reliable performance, high production efficiency, and low operating costs. In addition, the product remains free from contamination during the process, as there are no intermediate handling steps.

This machine is widely used for the production of containers in the food, beverage, cosmetics, and pharmaceutical industries.

Filling Speed: 18000BPH | 24000BPH | 36000BPH | 48000BPH | 56000BPH

Filling Bottle Size: 250ml | 330ml | 500ml | 600ml | 750ml | 1L | 1.5L | 2L

Suncrown Machine, a trusted manufacturer of beverage and water production & filling machinery, provides advanced filling solutions to meet the highest hygiene and performance standards. Our Dry Aseptic Cold Filling System utilizes cutting-edge technology, making it the ideal choice for premium products such as juice, tea, functional drinks, plant-based beverages, and dairy-based drinks that require maximum protection of nutrients and taste.

✅ 1. Dry Sterilization – Water-Saving and Eco-Friendly

Using H₂O₂ (hydrogen peroxide) dry mist sterilization, both bottles and caps are effectively sterilized without the need for large volumes of water or chemical rinses. This environmentally friendly method reduces wastewater and supports sustainable production.

✅ 2. Cold Filling – Preserve Nutrients and Flavor

Products are filled at ambient temperatures in an aseptic environment, preventing heat damage to sensitive ingredients. This process retains natural taste, nutrients, and bioactive components, especially suitable for heat-sensitive premium beverages.

✅ 3. Fully Sealed Aseptic Filling Environment

The system is equipped with a HEPA filtered clean air system, maintaining a Class 100 sterile environment within the filling zone. This ensures protection against airborne contaminants and guarantees microbiological safety.

✅ 4. Automated Control & Real-Time Monitoring

Integrated PLC control with HMI touchscreen interface allows for automated operation and real-time monitoring of key parameters such as temperature, pressure, flow rate, and sterilant concentration—ensuring product quality and operational reliability.

✅ 5. Modular Design – Seamless Line Integration

The system is designed to integrate seamlessly with upstream processing units (like UHT sterilizers and blending systems) and downstream packaging lines. It supports quick changeover between various bottle types and sizes, enabling flexible production.

✅ 6. Extended Shelf Life Without Preservatives

Thanks to strict aseptic control and cold filling technology, products achieve a longer shelf life without the need for chemical preservatives, helping brands deliver healthier, cleaner-label products.

✅ 7. International Standards & Global Support

Suncrown’s aseptic filling systems comply with FDA, CE, and GMP standards, and we provide end-to-end service including project design, equipment manufacturing, on-site installation, training, and long-term technical support with an experienced global team.

| Product model | GGF10 | GGF16 | GGF20 | GGF24 | GGF30A | GGF30B |

| Capacity | 18000 | 24000 | 30000 | 36000 | 48000 | 56000 |

| Module parts | 40-10 | 56-16 | 70-20 | 80-24 | 100-30 | 120-30 |

| Bottle type | 200m1-2000ml | |||||

| Sterilization type | H₂O₂ Dry sterilization 36 | |||||

| Sterilization efficiency | ≥6 | |||||

| Beverage type | Fruit particle Juice,Tea,Sodawater,milk beverage etc | |||||