Home / About Us

Suncrown Machine is a modern enterprise specializing in turnkey solutions for food and beverage production lines. We integrate R&D, product design, manufacturing, and after-sales service to deliver one-stop solutions.

Founded at the beginning of the century, Suncrown has rapidly expanded to include several subsidiaries:

1.Suncrown Machine Intelligent Equipment Co., Ltd.

2.Zhengzhou Suncrown Machinery Co., Ltd.

3.Langfang Suncrown Machine Packaging Machinery Co., Ltd.

4.Beijing Suncrown Machine Food Technology Co., Ltd.

5.Xinjiang Suncrown Machine

We’ve also established offices in Yunnan, Nanjing, Kazakhstan, and Italy.

Our main production base is in Siyang, Jiangsu Province—located in the vibrant Yangtze River Delta and Huaihai Economic Zones.

Suncrown Machine Intelligent Equipment Co., Ltd. is committed to the design, development and manufacturing of liquid packaging intelligent equipment, the company has a production base of nearly 80,000 square meters in Siyang Development Zone, Jiangsu Province, and the modern factory area has a technology research and development center, experimental testing center, production and processing workshop, assembly and assembly workshop, warehousing and logistics center, office building, living area, etc., the regional division is reasonable, and the supporting facilities are readily available, providing a reliable guarantee for the design, research and development, manufacturing and service of liquid intelligent packaging equipment.

The company’s business mainly covers neutral beverages, acidic beverages, carbonated beverages, wine, water, oil, canned food, condiments, pharmaceuticals and other equipment and related supporting equipment, the company’s professional sales, technology and engineering team can provide customers with one-stop professional services such as product shape design, beverage product formula, plant layout design, process design and consulting, equipment design and production, installation and commissioning.

At present, the company’s main production line series include:

*PET aseptic cold filling line

*Can production lines

*Glass bottle food and beverage production line

* PET water/beverage production line

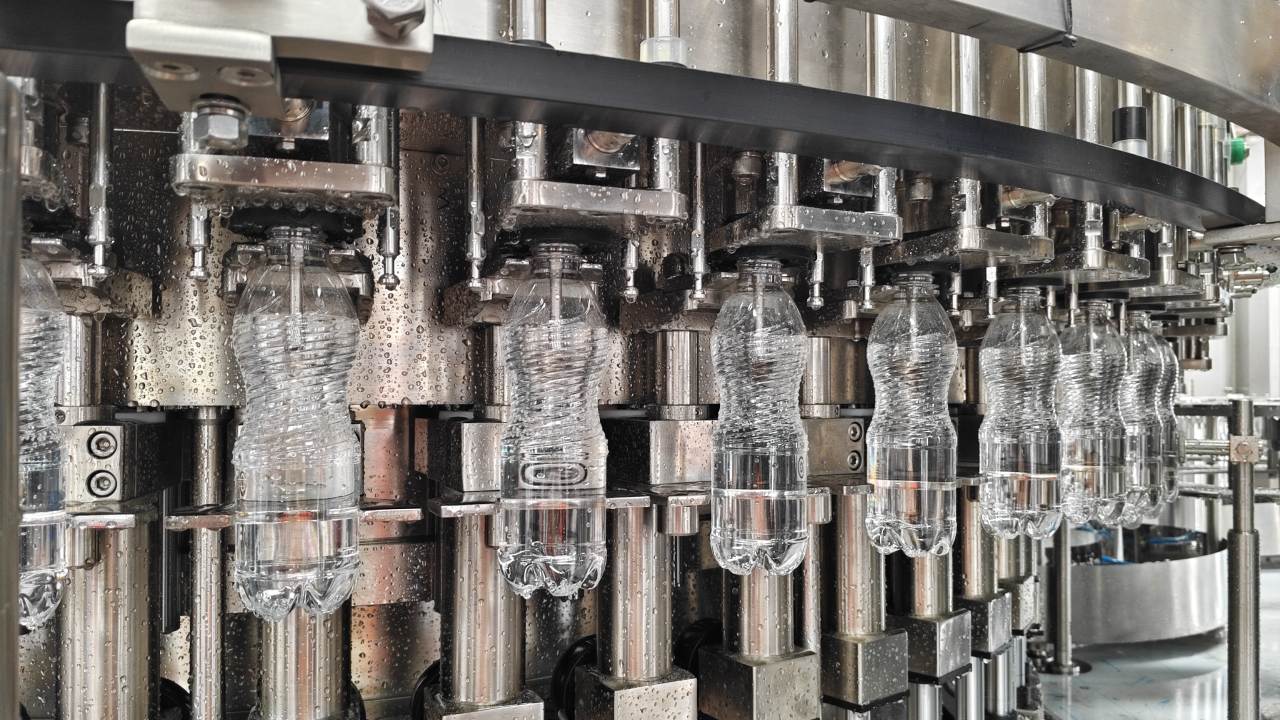

The main products include: water treatment system, pre-blending system, PET aseptic cold filling production line related equipment, can/can production line related equipment (mainly including automatic depalletizer, filling and sealing machine, automatic loading and unloading machine, robot palletizer, automatic packing machine, etc.), Babao porridge production line special products (automatic Babao porridge capping machine, automatic longan adding machine, automatic lotus seed adding machine, etc.), glass bottle beverage production line related equipment, PET water/ Beverage production line related equipment (including bottled water filling, medium temperature filling, ultra-clean filling, blowing, filling and spinning, etc.).

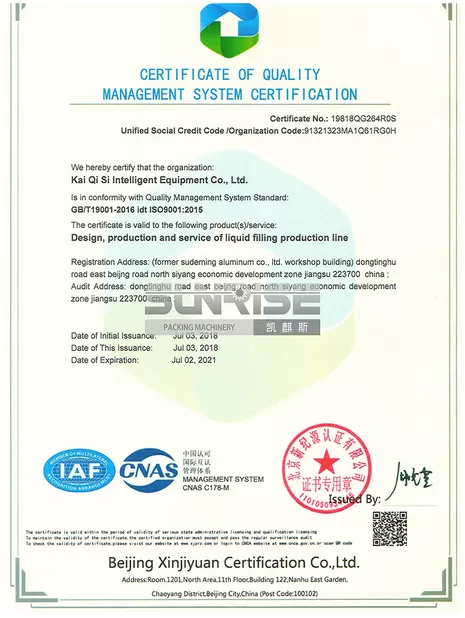

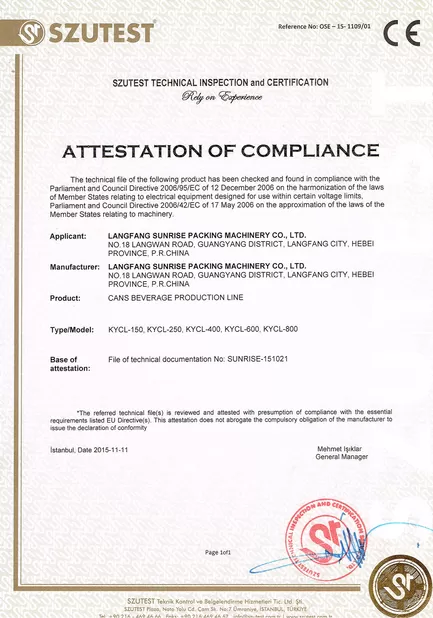

Suncrown Machine has a high-quality, highly educated, high-quality, highly team spirit and innovative spirit of staff. The company has more than 300 employees, including nearly 100 professional and technical personnel. At present, the company mainly has financial department, administrative personnel department, marketing center, engineering center, production and operation center, chief engineer’s office, filling division, post-packaging division and other departments. The relevant personnel have rich experience in the design, production, processing and assembly of the machinery industry. At the same time, the company continues to improve the level of comprehensive management, the company has passed the ISO9001-2016 quality management system certification, the company’s products have passed the EU CE certification, and the implementation of ERP management system and CRM management system, with a complete management system, to provide guarantee for product quality.

After years of development, the company has become a member of China Food and Packaging Machinery Industry Association, China Light Industry Machinery Association, China Beverage Industry Association, and China Canned Food Industry Association. The company’s products are sold all over the country and the international market, so far the company has been Huizhou Yelia Food, Tumen Jiang Pharmaceutical, Xiamen Yinlu Group, Hainan Coconut Cow Group, JDB, Wanglaoji, Yanjing Beer, Tsingtao Beer, Pearl River Beer, Jinmailang Beverage, Anhui Yangzi Group, Tongfu Bowl Porridge, Shanxi Yeshanpo, Yunnan Aodianao, Yunnan Grinding Agriculture, Yunnan Duoshang Juice, Fuling Mustard Group, Philippine MEGA Group, Turkmenistan NULI Group and many others have provided high-quality equipment and perfect services for food, liquid and beverage manufacturers.

Suncrown Machine boasts a large number of turnkey projects at home and abroad, and has completed more than 200 large turnkey projects for more than 20 countries around the world. At present, it is one of the few suppliers in the world who can complete the packaging line from PET granules to finished products.With years of unparalleled engineering experience, Suncrown Machine has rich experience in serving end users and integrators. And with our powerful service system, we stand poised to unlock exceptional levels of efficiency and adaptability for our valued customers.

Suncrown Machine high-speed liquid packaging production line

Suncrown Machine high-speed liquid packaging production line products cover water treatment, beverage processing, BFC combi-block, injection molding, blow molding, filling, conveying, labeling, packaging and other series. Over the years, hundreds of production lines have been successfully applied all over the world, with the production efficiency of the whole line higher than 85% and the yield higher than 99.5%.

Suncrown Machine is well-versed in every aspect of the liquid product packaging system and has harnessed this expertise to develop an automation solution based on the signature technology. As we enter the era of new industrial revolution, Suncrown Machine is committed to transforming its production mode by implementing an advanced automation system that enables us to deliver cutting-edge solutions that are catered towards the future.

85%: The production efficiency of the whole line is higher than 85%

99.5%: The yield is higher than 99.5%.

At the beginning of its establishment, the company was committed to the design, development and manufacture of intelligent liquid packaging equipment. The modern factory has a Jiangsu Industrial design center, a technology research and development center, an experimental testing center, a production and processing workshop, an assembly workshop, a warehousing and logistics center, an office building, a living area, etc. The area is reasonably divided and the supporting facilities are readily available. It provides a reliable guarantee for the design, research and development, manufacturing and service of liquid intelligent packaging equipment.

Machining and assembly

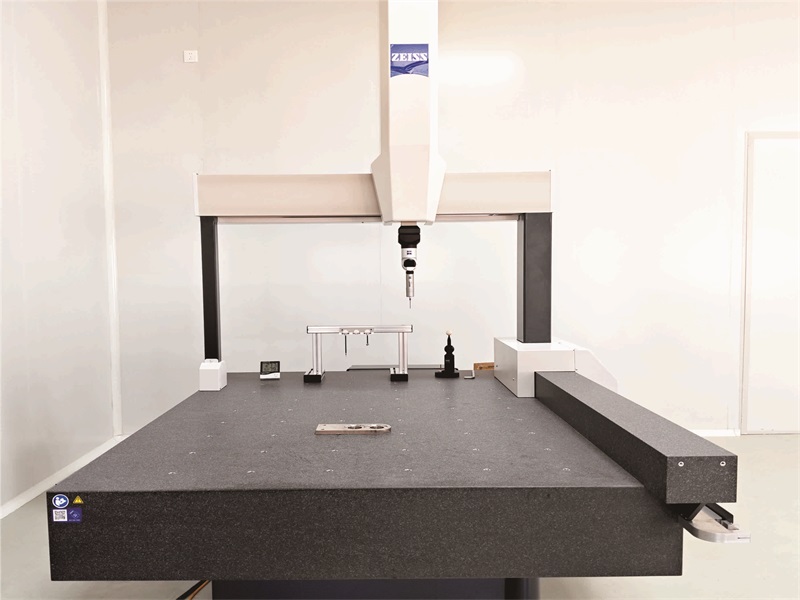

The company’s production and processing strength: Through continuous development, the company’s production capacity can reach an annual output of 90-120 sets of main intelligent equipment and equipment, 30-40 cans, glass bottles, and PET whole lines, and 5-10 aseptic production lines.The company has built a number of production workshops such as riveting and welding cutting workshops, machining workshops and finished product assembly workshops, and has dozens of intelligent processing equipment of various types such as well-known brand gantry machining centers, German Zeiss three-coordinate measuring machines, CNC horizontal turning machines, CNC vertical lathes, vertical machining centers, horizontal machining centers, and turning centers.

Strong R&D strength of aseptic filling production line

The company as a whole covers an area of more than 200 acres, with a construction area of nearly 80,000 square meters, and has more than 450 employees, including nearly 80 R&D and design personnel for aseptic cold filling technology.

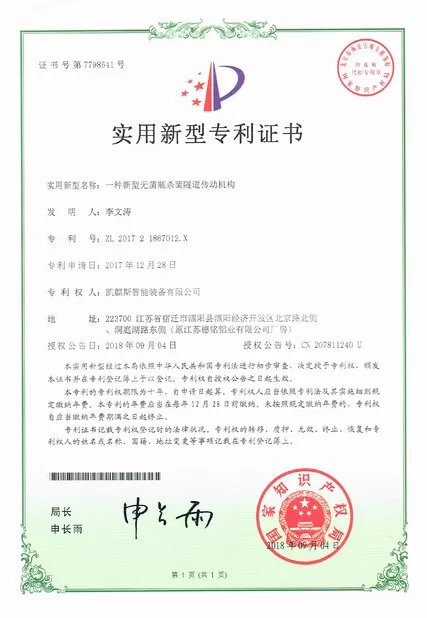

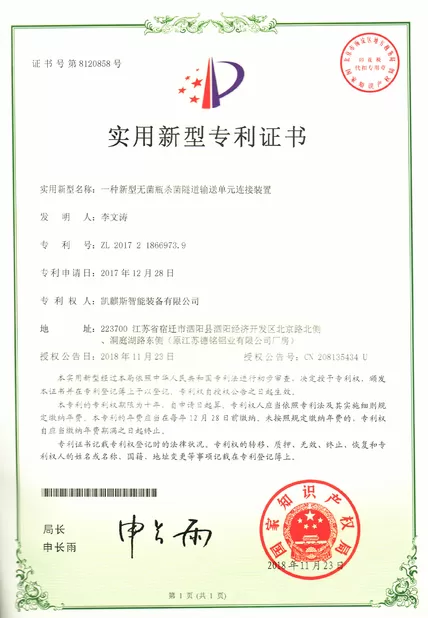

Suncrown Machine’s design team all adopts CAD, CAXA, AND SOLIDWORKS design and drawing software, and applies three-dimensional drawing software for product research and development and design. All technical personnel are college students and above, and they have many years of experience in mechanical and whole-line engineering design. After continuous efforts and research and development innovation, The company’s product technology level is currently at the leading level in the same industry, and there are more than 100 kinds of products that have been developed, produced and matured.The market share of the company’s related products has been far ahead.At present, more than a dozen products of the company have obtained national patent certificates.At the same time, the company has long hired senior experts from Hebei University of Science and Technology, Hebei University, Beijing University of Technology, and Hunan University as company consultants to guide the company’s product research and development and design in food and beverage packaging production line equipment, and established a “production”, “learning” and “research” cooperative relationship with Hebei Normal University of Science and Technology, which has laid a solid foundation for the company’s long-term development.

Excellent quality control and inspection system

As a leading enterprise that has passed the national quality management system certification, we always control the quality of each equipment with strict standards.The introduction of cutting-edge equipment such as the German Zeiss three-coordinate inspection machine ensures that the accuracy of parts reaches the micron level, which provides a guarantee for efficient and stable packaging performance.

Our quality inspection team is composed of experienced technical elites, with lean control from R&D to production, perfect staffing and rapid service response.Whether it is standardization or customization requirements, we can deliver high-quality equipment that customers are satisfied with with excellent technology and rigorous attitude.

After-sales service system

To provide customers with comprehensive personnel technical training programs, improve the quality of maintenance and the ability to deal with failures, and improve the efficiency of equipment work.

Equipped with an experienced team of engineers, it provides a 7×24-hour response to ensure that your production line has no worries.

Service engineers participate in the customer’s production and equipment maintenance process in stages, carefully study the operating quality and problems of the customer’s equipment, and provide reasonable and detailed analysis reports and optimization suggestions.For each customer’s on-site equipment model, three-level spare parts inventory management is implemented: factory inventory of general parts, customer inventory of customized parts, and supplier inventory of important parts to minimize unplanned downtime.Whether it is on-site rapid support or remote diagnostic guidance, we can solve the problem efficiently.From installation and commissioning to daily maintenance, from technology upgrade to spare parts supply, we provide full life cycle services for beverage terminal manufacturers to escort your stable operation!