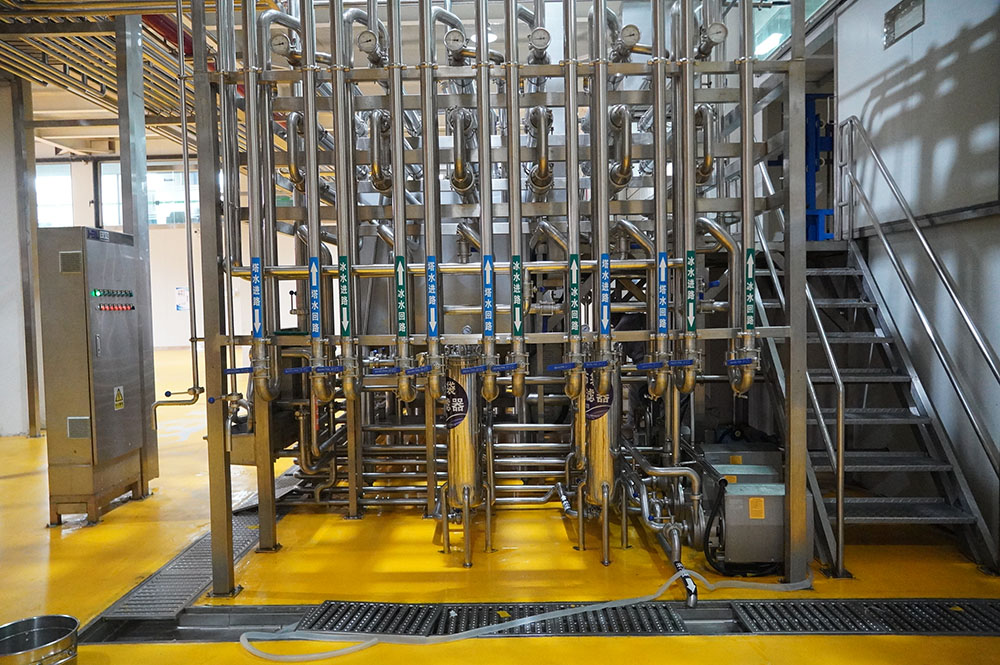

The blending system is an integrated solution that dissolves and mixes raw materials, auxiliary ingredients, and process water through modules such as hot water, sugar filtration and sterilization, juice or tea powder dissolution, milk or tea extraction, blending, and CIP cleaning. With a professional design and engineering team, Suncrown Machine ensures product quality through precise design, advanced automation, and rich experience from over 2,000 large-scale installations.

Storage tank:

Our company's storage tank series strictly follows the requirements of Article 31 and 32 of the GMP General Principles of Good Manufacturing Practice for Pharmaceuticals (revised in 1998), and is designed, manufactured and accepted in accordance with the requirements of Steel Pressure Vessels (GB150-1998) and Steel Welded Atmospheric Pressure Vessels (JB/T4735-1997). The interface adopts the international standard quick-release chuck type, imported 316L or 304, the inner surface is mirror polished Ra≤0.4μm, and the outer surface is matte, mirror or 2B primary color.

The pipe mouth has a level gauge interface, a respirator interface, a thermometer interface, a CIP cleaning port, a sight glass, an explosion-proof sight light, a SIP sterilization port, a liquid inlet and outlet, and a manhole.

Fermentation tank:

Fermentation tank is widely used in dairy products, beverages, bioengineering, pharmaceuticals, fine chemicals and other industries. The tank body is equipped with interlayer, insulation layer, heating, cooling and insulation. The tank body and upper and lower filling heads (or cones) are processed by spinning R angle. The inner wall of the tank is mirror polished, without sanitary dead corners, and the fully enclosed design ensures that the materials are always mixed and fermented in a pollution-free state. The equipment is equipped with air breathing holes, CIP cleaning nozzles, manholes and other devices.

Blending tank

Blending tank has the advantages of energy saving, corrosion resistance, strong production capacity, easy cleaning and simple structure. It is mainly used for mixing dairy products, sugar and other elements with various drugs. It is an indispensable equipment for dairy products, beverages and pharmaceutical factories. The material is SUS304 or 316 stainless steel.

The UHT high temperature instantaneous sterilization temperature is 135-140℃, and the heat preservation is 4 seconds to meet the commercial aseptic requirements. It is a sterilization process for fresh milk, cereal beverages and beverages. It does not need to be stored at room temperature, and the shelf life can reach 1-6 months.

Aseptic tank

Aseptic tank is mainly installed between high temperature and aseptic canning machines, acting as a buffer. Its advantage is that it can avoid the backflow of high temperature sterilizer, which can ensure the quality of milk and juice. Milk and juice can be canned in the canning machine after only one sterilization. Moreover, when the canning machine has problems and cannot be canned, the sterilizer and aseptic tank can still work, and the high temperature produced milk can continue to be temporarily stored in the aseptic tank. In this way, when the canning machine is repaired, the material in the aseptic tank can continue to be canned in the canning machine. There is no need to run the high temperature sterilizer for production. Using aseptic tanks will greatly reduce the cost of the enterprise and improve the product quality of the enterprise.

Why Choose Suncrown Machine’s Processing System?

As a leading manufacturer specializing in beverage and water production & filling machinery, Suncrown Machine not only offers high-efficiency and reliable filling equipment, but also delivers advanced liquid processing systems to ensure your raw materials are in optimal condition before entering the filling stage. Our Processing Systems are widely applied in industries such as bottled water, juice, carbonated drinks, tea beverages, functional drinks, and dairy products.

✅ 1. Professionally Matched for Various Beverage Formulas

Suncrown provides customized liquid blending systems, allowing precise control over the ratio of syrup, flavorings, concentrates, dairy ingredients, and additives—ensuring consistent taste and product quality.

✅ 2. High-Efficiency Mixing and Homogenizing Technology

Equipped with high-shear mixers, homogenizers, and vacuum degassing equipment to ensure uniform mixing and a delicate mouthfeel. This also helps prevent foaming and oxidation, thereby extending shelf life.

✅ 3. Precise Temperature Control & Sterilization

We offer multiple sterilization solutions, such as plate-type pasteurization and UHT (ultra-high-temperature) instant sterilization, which effectively control microbes while preserving nutrients and taste—ideal for dairy, tea, and premium functional beverages.

✅ 4. Modular System Design with Flexible Expansion

Our processing systems can be configured flexibly based on your production capacity and product type, making it easy to scale from pilot batches to full-scale commercial production.

✅ 5. Food-Grade Manufacturing, International Standards

All contact parts are made of food-grade 304/316 stainless steel, complying with GMP and HACCP international food safety standards to ensure product hygiene and safety.

✅ 6. Automated Control to Save Labor Costs

Integrated PLC control system with touchscreen interface enables intelligent management of recipes, automatic ingredient dosing, temperature regulation, flow metering, CIP cleaning, and more—boosting production efficiency and reducing manual operations.

✅ 7. Global Support & Tailored Services

With over 15 years of export experience, Suncrown provides global clients with project design, technical consultation, on-site installation, and operator training, helping you build and operate your factory with confidence and speed.