Home / Aseptic Filling Lines

Filling Speed: 18000BPH | 24000BPH | 36000BPH | 48000BPH

Filling Bottle Size: 250ml | 330ml | 500ml | 600ml | 750ml | 1L | 1.5L | 2L

Filling Speed: 18000BPH | 24000BPH | 36000BPH | 48000BPH | 56000BPH

Filling Bottle Size: 250ml | 330ml | 500ml | 600ml | 750ml | 1L | 1.5L | 2L

Modern beverage brands face increasing challenges:

❌ Short shelf life affecting distribution and sales

❌ Use of preservatives that compromise product purity

❌ High energy and water consumption during filling

❌ Complex cleaning and sterilization processes

To meet growing consumer demand for natural, long-lasting beverages without additives — a new standard in beverage processing is essential.

Suncrown offers two advanced aseptic cold filling technologies, designed to deliver microbiological safety, longer shelf life, and lower operational cost:

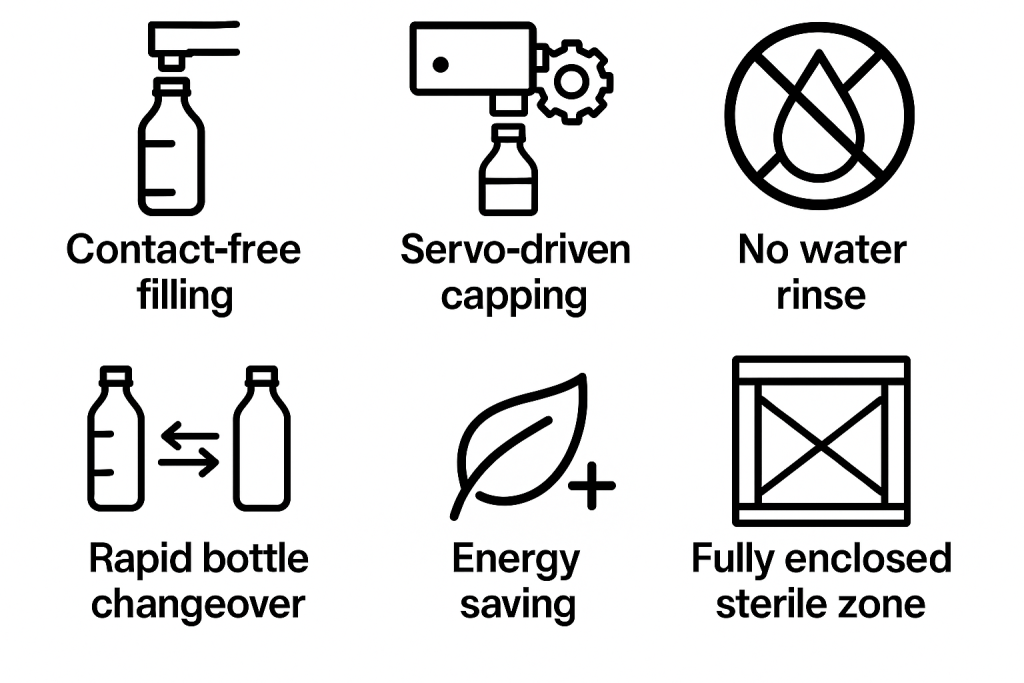

No need for disinfectant rinsing or sterile water

Compact design, lower energy & water use

Perfect for premium beverages like milk, juice, tea, and protein drinks

Fast changeover without bottle format parts

Minimal chemical usage — eco-friendly & cost-saving

Reliable, proven solution using disinfectant + sterile water rinse

Ideal for large-scale production of juices, teas, and beverages

Trusted by factories worldwide with high-volume demand

| Feature |

|

|

| Model | Wet Aseptic Cold Filling Blowing, Filling and Capping 3 in 1 Machine | Dry Aseptic Cold Filling Blowing, Filling and Capping 3 in 1 Machine |

| Disinfection Method | Liquid disinfectant + rinse water | Dry sterilant mist |

| Bottle Rinsing Required | ✅ Yes | ❌ No |

| Water & Chemical Consumption | 90% useful | Low |

| Aspect Ratio | 20:9 | 20:9 |

| Space Saving | ❌ Larger footprint | ✅ Compact design |

| Ideal For | Mass production | High-end beverages |

It is suitable for such water treatment equipment as pure water, mineral water, and beverage process water. It is mainly composed of the following equipment: Pre-treatment System (multi-medium filter, active carbon filter, ion exchanger, Millipore filter), membrane separation System (Ultrafilter, nanometer filter, RO System), electrodialysis device, sterilization System (UV device, ozone device) and so on.

The blending system refers to a combination of equipment that extracts or dissolves various raw materials, auxiliary materials and process water through various process units according to predetermined process parameters, and then mixes and blends to obtain semi-finished products; the main modules include hot water unit, sugar filtration and sterilization unit, juice/tea powder reduction and dissolution unit, auxiliary material dissolution unit, tea extraction and filtration unit, milk powder reduction and mixing unit, blending and volume setting unit, CIP cleaning unit, pipeline unit, electrical control and central control unit, etc.

The aseptic cold filling production line integrates and optimizes multiple advanced technologies, including cleaning and sterilization, sterile isolation, microbiological monitoring and control, air purification, filling and sealing, and automated control. It is specifically designed for the production of acidic beverages, non-protein neutral beverages, and certain protein-based neutral beverages.

This equipment extends the flexibility of beverage filling processes and effectively preserves the nutritional content, flavor, and color of the beverage—making it particularly suitable for heat-sensitive drinks. Additionally, it provides extensive potential for diversified product appearance design and significantly reduces PET bottle costs.

Suncrown Labeling Machine is designed for precise, high-speed labeling of bottles, cans, and containers in beverage and food production lines. Compatible with various label types such as PVC shrink sleeves, OPP hot melt labels, and self-adhesive stickers, it ensures smooth operation, accurate positioning, and a clean, professional finish. Equipped with intelligent sensors, PLC control, and quick-change features, our labeling systems improve production efficiency while maintaining top-quality appearance.

Suncrown Shrink Wrapping and Case Packing Systems provide efficient, automated solutions for end-of-line packaging in beverage and food production. Our shrink wrapping machines tightly bundle bottles or cans with heat shrink film, ensuring secure and compact packaging. For higher protection and stacking needs, our wrap-around case packers form corrugated boxes around product groups with precision and speed. Designed for seamless integration, these machines boost packaging efficiency, save labor, and enhance your product’s shelf-ready presentation.

Suncrown Palletizing Systems offer reliable and flexible end-of-line solutions for stacking cartons, shrink-wrapped packs, or trays onto pallets. Available in both robotic and semi-automatic configurations, our systems are designed to optimize space, reduce manual labor, and increase palletizing efficiency. With customizable stacking patterns, smooth operation, and easy integration into your existing line, Suncrown palletizers ensure stable loads and streamlined logistics for high-speed production environments.

Answer:

Aseptic filling is ideal for beverages that require long shelf life without preservatives. This includes fruit juices (with or without pulp), milk, dairy-based drinks, plant-based beverages (soy, oat, almond), functional drinks, RTD coffee, and tea-based drinks. Suncrown offers both wet and dry aseptic systems tailored to different pH levels and product sensitivities.

Answer:

Wet aseptic uses sterilizing liquids (like peracetic acid) and sterile water for bottle/container disinfection.

Dry aseptic uses ionized air or vaporized hydrogen peroxide (VHP) — offering less water consumption, smaller equipment footprint, faster changeovers, and more eco-friendly operation. Suncrown specializes in both, with dry aseptic preferred for high-end drinks like dairy, coffee, or functional beverages.

Answer:

Beverages filled with an aseptic system can last up to 6–12 months at room temperature, depending on the formula and packaging. This eliminates cold chain logistics, significantly reducing operational costs and expanding distribution reach — especially in hot regions like the Middle East or Africa.

Answer:

Suncrown aseptic filling systems support PET bottles, HDPE bottles, glass bottles, and even Bag-in-Box or stand-up pouches (upon request). For PET bottles, our solution includes in-line bottle blowing, non-contact filling, and servo capping, all in a sterile chamber.

Answer:

We use a fully enclosed sterile chamber, paired with CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems. All key zones are protected by HEPA filters, and contact surfaces are made of food-grade stainless steel (316L/304). Real-time monitoring and PLC control ensure traceability and compliance with international aseptic standards (FDA, EHEDG, ISO 22000).