Home / PET Beverage Filling Line

Filling Speed: 10000BPH | 12000BPH | 18000BPH | 24000BPH | 36000BPH | 48000BPH

Filling Bottle Size: 250ml | 330ml | 500ml | 600ml | 750ml | 1L | 1.5L | 2L

| Product model | GQ08A | GQ10A | GQ15A | GQ20A | GQ25A |

| Capacity | 10000 | 12000 | 24000 | 36000 | 48000 |

| Bottle type | 250ml-2000mlmulti shaped bottle type | ||||

| Beverage type | Cola,soda,carbonatedsoda water,etc | ||||

Suncrown Machine is a global manufacturer with over 15 years of experience in designing, manufacturing, and installing complete beverage production lines. From water and juice to carbonated soft drinks and milk, we provide customized turnkey solutions tailored to your product, capacity, and market needs. Our clients in 50+ countries trust us for stable machines, smart automation, and local service support.

It is suitable for such water treatment equipment as pure water, mineral water, and beverage process water. It is mainly composed of the following equipment: Pre-treatment System (multi-medium filter, active carbon filter, ion exchanger, Millipore filter), membrane separation System (Ultrafilter, nanometer filter, RO System), electrodialysis device, sterilization System (UV device, ozone device) and so on.

The blending system refers to a combination of equipment that extracts or dissolves various raw materials, auxiliary materials and process water through various process units according to predetermined process parameters, and then mixes and blends to obtain semi-finished products; the main modules include hot water unit, sugar filtration and sterilization unit, juice/tea powder reduction and dissolution unit, auxiliary material dissolution unit, tea extraction and filtration unit, milk powder reduction and mixing unit, blending and volume setting unit, CIP cleaning unit, pipeline unit, electrical control and central control unit, etc.

Suncrown Machine offers high-efficiency, stable, and fully automated carbonated beverage filling machines, suitable for a wide range of products including carbonated soft drinks, soda water, sparkling water, flavored sodas, and energy drinks.

The equipment integrates bottle rinsing, isobaric filling, and capping into a single monoblock system. It adopts isobaric (equal pressure) filling technology, which effectively preserves carbon dioxide, ensuring long-lasting carbonation and consistent taste.

This machine is an ideal choice for medium- to high-end carbonated beverage manufacturers seeking quality, performance, and automation.

Suncrown Labeling Machine is designed for precise, high-speed labeling of bottles, cans, and containers in beverage and food production lines. Compatible with various label types such as PVC shrink sleeves, OPP hot melt labels, and self-adhesive stickers, it ensures smooth operation, accurate positioning, and a clean, professional finish. Equipped with intelligent sensors, PLC control, and quick-change features, our labeling systems improve production efficiency while maintaining top-quality appearance.

Suncrown Shrink Wrapping and Case Packing Systems provide efficient, automated solutions for end-of-line packaging in beverage and food production. Our shrink wrapping machines tightly bundle bottles or cans with heat shrink film, ensuring secure and compact packaging. For higher protection and stacking needs, our wrap-around case packers form corrugated boxes around product groups with precision and speed. Designed for seamless integration, these machines boost packaging efficiency, save labor, and enhance your product’s shelf-ready presentation.

Suncrown Palletizing Systems offer reliable and flexible end-of-line solutions for stacking cartons, shrink-wrapped packs, or trays onto pallets. Available in both robotic and semi-automatic configurations, our systems are designed to optimize space, reduce manual labor, and increase palletizing efficiency. With customizable stacking patterns, smooth operation, and easy integration into your existing line, Suncrown palletizers ensure stable loads and streamlined logistics for high-speed production environments.

Answer:

Suncrown’s PET carbonated beverage filling line is suitable for a wide range of fizzy drinks, including carbonated soft drinks (CSD), soda water, flavored sparkling water, energy drinks, tonic water, and low-alcohol beverages. The line can be customized for different CO₂ volumes and carbonation levels.

Answer:

Our system uses isobaric (equal pressure) filling valves that minimize foaming and CO₂ loss during the filling process. The machine operates under constant pressure and cold filling temperature (typically 2–4°C), ensuring high carbonation retention and beverage quality.

Answer:

We support a wide range of PET bottle sizes from 250ml to 2.5L, including custom bottle shapes. Quick-change neck guides and format parts allow for fast bottle size switching, reducing downtime and increasing productivity.

Answer:

Yes. Our carbonated beverage filling lines are compatible with both pre-mix (ready carbonated beverage) and post-mix (carbonation in-line just before filling) setups. We also provide carbonators, mixing tanks, and CO₂ injection systems to complete your beverage processing needs.

Answer:

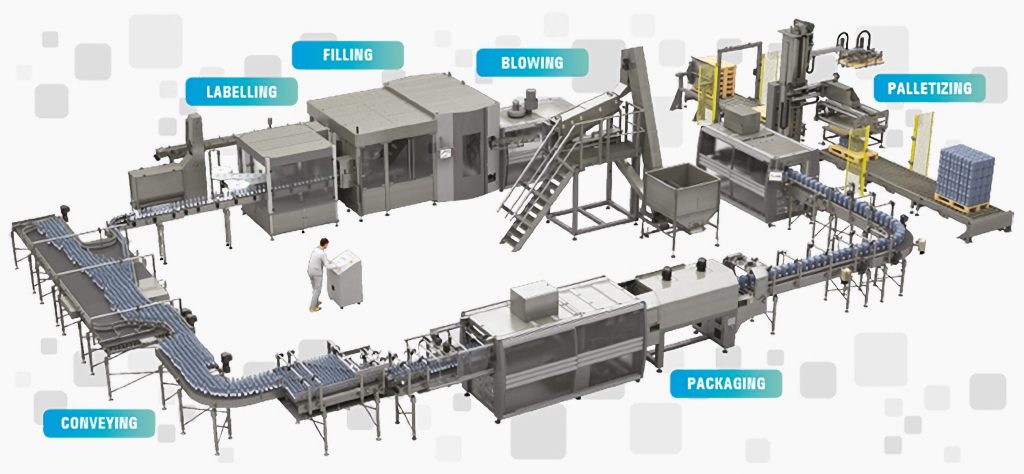

A standard line includes:

Bottle blowing machine (optional)

Bottle rinser, isobaric filler, and capper (3-in-1)

CO₂ mixing and carbonation system

Labeling machine

Shrink wrapping or case packing system

Air conveyor and cooling tunnel

All systems are fully automated and built with 304/316 food-grade stainless steel.