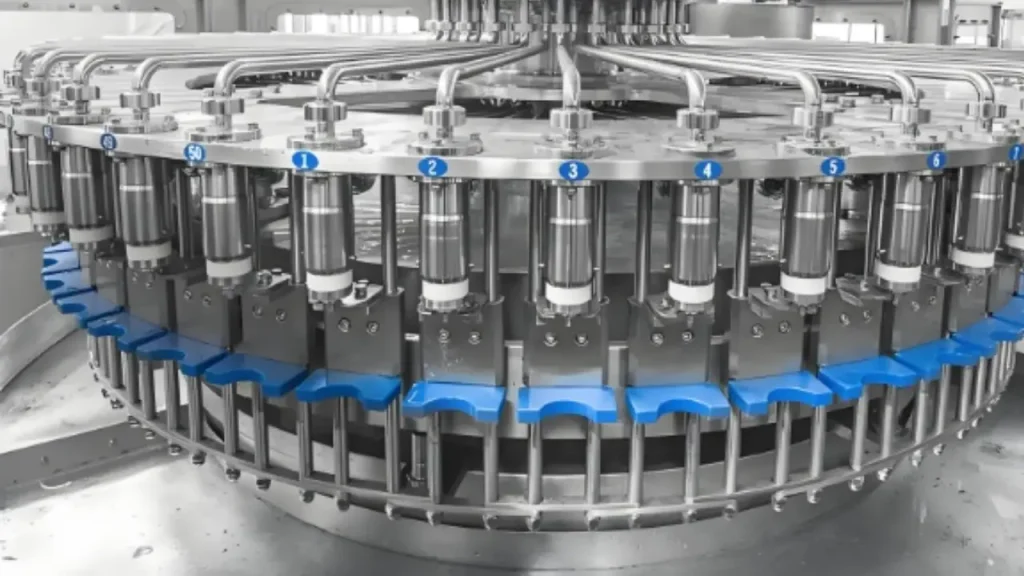

The ultra-clean filling equipment adopts an ultra-clean filling process, ensuring a sterilization efficiency (SE) greater than 10³ (SE > 3) for contact surfaces between packaging materials and the product. The filling and capping areas are designed to meet the Class N6 cleanroom standards as specified in GB50073-2013, Design Code for Cleanrooms.

Filling Speed: 12000BPH | 18000BPH | 24000BPH | 36000BPH | 48000BPH

Kích thước chai chiết rót: 200 ml | 330 ml | 500 ml | 600 ml | 750 ml | 1 L | 1,5 L

Empty bottles are conveyed using an air conveyor equipped with high-efficiency filters, ensuring hygienic transfer and protection from secondary contamination. Prior to filling, bottles undergo multi-stage rinsing and sterilization, achieving a high level of cleanliness. A non-contact filling method is used to further ensure hygienic standards during the filling process.

Bottle caps are immersed in disinfectant solution for sterilization, then dried with sterile water and sterile air. The treated caps are delivered to the capping machine via a sealed, sterile tunnel, maintaining their sterile condition throughout the process.

The beverage product is subjected to ultra-high temperature (UHT) instantaneous sterilization, and then transferred to an aseptic storage tank before being delivered to the filling machine. The piping system is mirror-polished, equipped with aseptic-grade fittings, hygienic/aseptic valves, and instruments. The entire system is designed and constructed to eliminate sanitary dead zones, ensuring aseptic conditions during product transfer.

The filling environment is a fully enclosed system, with double water ring seals isolating the filling area from the external environment. An optimized FFU (Fan Filter Unit) configuration is combined with proper exhaust vents to maintain clean airflow. The rinsing and filling zones are separated by partitions, ensuring the filling area meets ISO Class 5 (Class 100) cleanroom standards. The cleanroom is equipped with dual CIP systems (spray balls and spray nozzles), and the worktable adopts a roof-type slope design to prevent water accumulation, ensuring aseptic conditions in the filling environment.

Applicable Products: Juice, tea beverages, functional drinks, dairy-based beverages

Applicable Containers: PET bottles of various shapes and capacities

| Applicable products | Fruit juice,Tea drinks,Functional drinks,Milk-containing drinks, etc |

| Applicable Containers | PET bottles of various capacities and shapes |

| Filling Temperature | Hot filling(82-92℃),Medium temperature filling(68-75℃),Normal Temperature filling(16-35℃),low temperature cold filling(4-15℃) |

| Production Capacity | 12000Bottles/hour----48000Bottles/hour |