Accueil / Lignes de remplissage d'eau

Vitesse de remplissage : 10000BPH | 12000BPH | 18000BPH | 24000BPH | 36000BPH | 48000BPH | 54000BPH | 72000BPH

Taille de la bouteille de remplissage : 200ml | 330ml | 500ml | 600ml | 750ml | 1L | 1.5L

Suncrown Machine offre bien plus que des machines — nous fournissons une ingénierie complète et intelligente de lignes de production pour les usines d’eau en bouteille. Forts de plus de 15 ans d’expérience dans le secteur et d’installations réussies dans plus de 50 pays, notre équipe propose une planification personnalisée, un équipement fiable et un support local réactif. Que vous lanciez une nouvelle usine ou que vous mettiez à niveau une installation existante, Suncrown est votre partenaire de confiance, de la conception à l’exploitation.

| Product Model | GS08A | GS10A | GS15A | GS20A | GS25A | GS30A | GS35A |

| Capacity | 12000 | 18000 | 24000 | 36000 | 48000 | 54000 | 72000 |

| Modules | 24-8 | 32-10 | 40-15 | 60-20 | 80-25 | 90-30 | 110-35 |

| Washout Rate | 100% | ||||||

| Filling Liquid Level Error | ±3mm | ||||||

| Bottle Damage Rate | ≤0.08% | ||||||

| Damage Rate of Bottle Cap | ≤0.5% | ||||||

| Sealing Pass Rate | ≥99.7% | ||||||

| Capping Torque | 0.6~2.8N.m | ||||||

| Fluctuation Range | ±15% | ||||||

| Liquid Loss Rate | ≤0.3% | ||||||

Il convient aux équipements de traitement de l'eau tels que l'eau pure, l'eau minérale et l'eau de process pour les boissons. Il est principalement composé des équipements suivants : système de prétraitement (filtre multi-média, filtre à charbon actif, échangeur d'ions, filtre Millipore), système de séparation par membrane (ultrafiltre, filtre nanométrique, système RO), dispositif d'électrodialyse, système de stérilisation (appareil UV, appareil à ozone), etc.

Le système de mélange fait référence à une combinaison d'équipements qui extraient ou dissolvent diverses matières premières, matériaux auxiliaires et eau de procédé à travers différentes unités de processus selon des paramètres prédéterminés, puis les mélangent afin d'obtenir des produits semi-finis ; les modules principaux incluent l’unité d’eau chaude, l’unité de filtration et stérilisation du sucre, l’unité de réduction et dissolution de la poudre de jus/thé, l’unité de dissolution des matériaux auxiliaires, l’unité d’extraction et filtration du thé, l’unité de réduction et mélange de poudre de lait, l’unité de mélange et réglage du volume, l’unité de nettoyage CIP, l’unité de tuyauterie, l’unité de contrôle électrique et de contrôle central, etc.

La machine de remplissage d’eau de la série KSCGF intègre le rinçage des bouteilles, le remplissage et le capsulage en une unité entièrement automatisée. Elle est largement utilisée pour la production d’eau minérale en bouteille, d’eau purifiée, de boissons alcoolisées et d’autres boissons non gazeuses en bouteilles en plastique.

Cette série de machines de remplissage entièrement automatiques est conçue pour améliorer efficacement la capacité de production et la performance économique, répondant pleinement aux besoins des entreprises de production d'eau en bouteille

La machine d’étiquetage Suncrown est conçue pour un étiquetage précis et à haute vitesse des bouteilles, canettes et contenants dans les lignes de production de boissons et d’aliments. Compatible avec différents types d’étiquettes tels que les manchons rétractables en PVC, les étiquettes OPP thermofusibles et les autocollants adhésifs, elle garantit un fonctionnement fluide, un positionnement précis et une finition propre et professionnelle. Équipés de capteurs intelligents, d’un contrôle PLC et de fonctions de changement rapide, nos systèmes d’étiquetage améliorent l’efficacité de la production tout en maintenant une apparence de haute qualité.

Les systèmes d’emballage par rétraction et par conditionnement en carton de Suncrown offrent des solutions efficaces et automatisées pour l’emballage en fin de ligne dans la production de boissons et d’aliments. Nos machines de rétraction enveloppent solidement les bouteilles ou canettes avec un film thermorétractable, garantissant un emballage sécurisé et compact. Pour une protection accrue et des besoins d’empilage, nos conditionneuses en carton enveloppant forment des cartons ondulés autour des groupes de produits avec précision et rapidité. Conçues pour une intégration fluide, ces machines augmentent l’efficacité de l’emballage, réduisent la main-d’œuvre et améliorent la présentation prête-à-poser de vos produits.

Les systèmes de palettisation Suncrown offrent des solutions fiables et flexibles de fin de ligne pour l’empilage de cartons, de packs filmés ou de plateaux sur des palettes. Disponibles en configurations robotisées et semi-automatiques, nos systèmes sont conçus pour optimiser l’espace, réduire la main-d’œuvre et augmenter l’efficacité de la palettisation. Avec des schémas d’empilage personnalisables, un fonctionnement fluide et une intégration facile dans votre ligne existante, les palettiseurs Suncrown assurent des charges stables et une logistique simplifiée pour des environnements de production à grande vitesse.

La ligne de remplissage d’eau Suncrown convient à l’eau pure, l’eau minérale, l’eau alcaline et l’eau distillée. Elle supporte une large gamme de tailles de bouteilles, de bouteilles PET de 200 ml à 2 L, et peut être personnalisée pour les bouteilles en verre ou les contenants de 5 gallons sur demande.

Nos machines de remplissage d’eau sont disponibles en différentes capacités, de 2 000 bouteilles/heure à 24 000 bouteilles/heure, selon vos besoins de production. Nous proposons des systèmes linéaires et rotatifs pour répondre aux opérations d’embouteillage d’eau à petite, moyenne ou grande échelle.

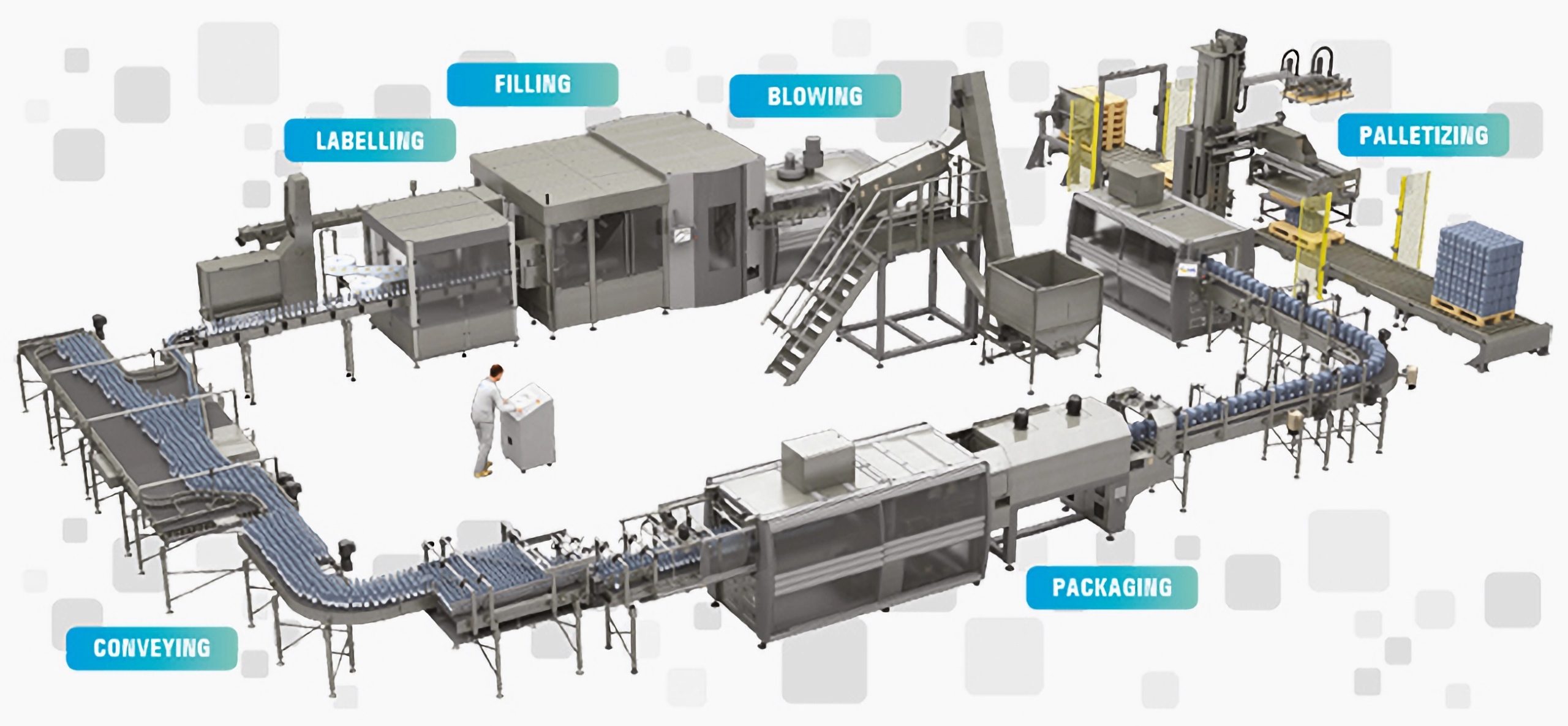

Une ligne complète de remplissage d’eau comprend :

Tous les équipements sont modulaires et personnalisables selon la configuration de votre usine.

Oui. Les machines Suncrown sont fabriquées en acier inoxydable de qualité alimentaire 304/316 et sont conformes aux normes CE, ISO et GMP. Le processus de remplissage est entièrement fermé et prend en charge le nettoyage en place (CIP) afin de répondre aux exigences d’hygiène des marchés du Moyen-Orient, d’Afrique, d’Asie et d’Europe.

Contactez simplement notre équipe avec votre capacité requise, la taille de la bouteille et le type de produit. Nos ingénieurs vous fourniront une mise en page personnalisée, une consultation technique et un devis gratuit sous 24 heures. Suncrown assure également l’installation sur site, la formation et le service après-vente dans le monde entier.