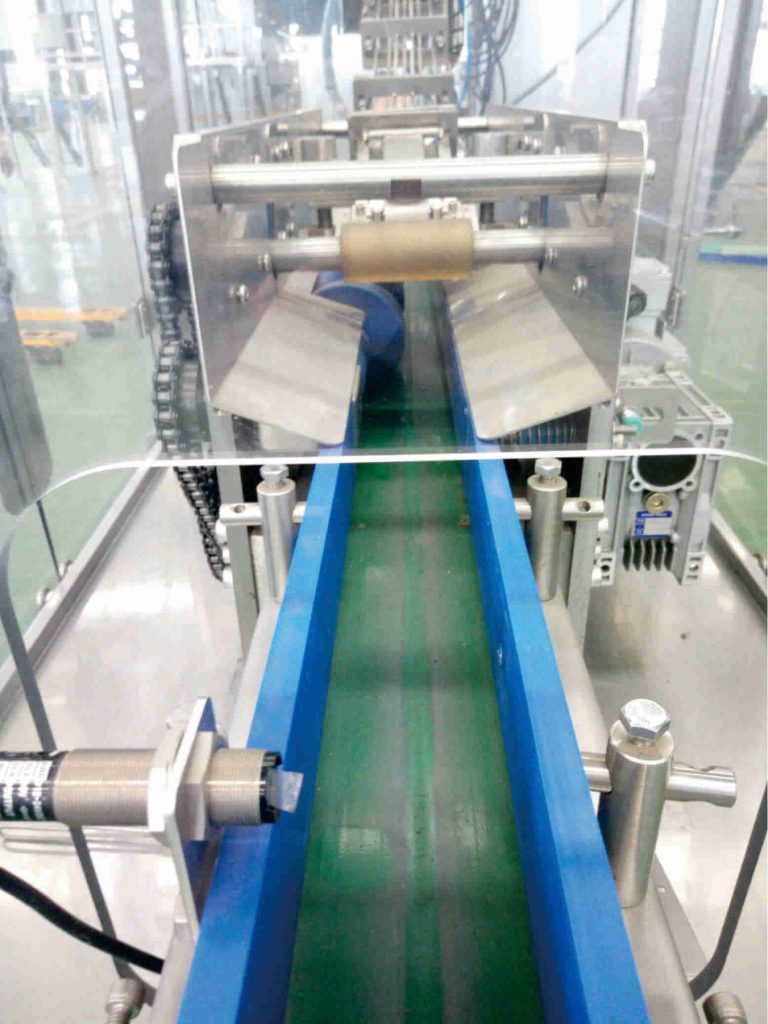

The Suncrown fully automatic plastic capping machine is specially designed for bottled water, beverages, dairy products, and other production lines. It is suitable for the automatic positioning and efficient capping of various plastic caps. Equipped with an intelligent servo control system, the machine ensures precise and secure capping without jamming or damaging the caps. It operates with high stability and reliability and can be seamlessly integrated with the filling line, significantly enhancing automation and production efficiency.