Suncrown Machine ofrece máquinas de llenado de bebidas carbonatadas de alta eficiencia, estables y totalmente automatizadas, adecuadas para una amplia gama de productos, incluidos refrescos, agua con gas, agua mineral con gas, refrescos saborizados y bebidas energéticas.

El equipo integra el enjuague de botellas, el llenado isobárico y el taponado en un solo sistema monobloque. Adopta la tecnología de llenado isobárico (a presión igual), que conserva eficazmente el dióxido de carbono, asegurando una carbonatación duradera y un sabor constante.

Esta máquina es una opción ideal para los fabricantes de bebidas carbonatadas de gama media a alta que buscan calidad, rendimiento y automatización.

Velocidad de llenado: 10000 BPH | 12000 BPH | 18000 BPH | 24000 BPH | 36000 BPH | 48000 BPH

Tamaño de la botella de llenado: 200 ml | 330 ml | 500 ml | 600 ml | 750 ml | 1 L | 1,5 L | 2L

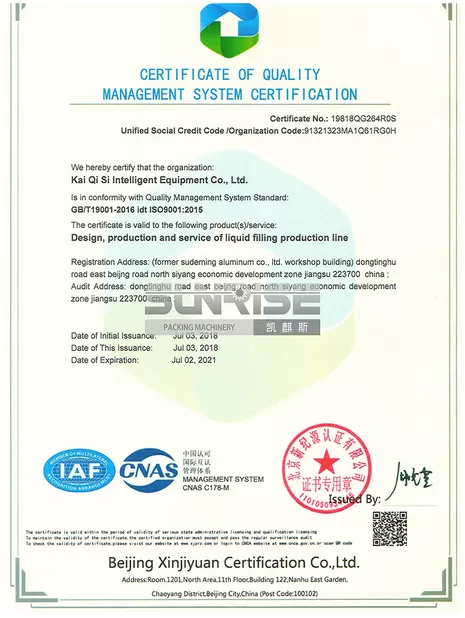

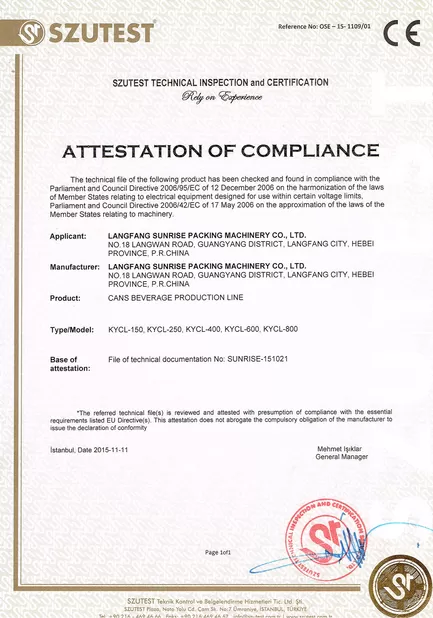

La máquina llenadora de bebidas carbonatadas se desarrolló sobre la base de años de experiencia en fabricación, combinada con la introducción, asimilación y absorción de tecnologías avanzadas tanto nacionales como internacionales.

Ofrece las siguientes ventajas clave:

Como una de las máquinas de producción de bebidas carbonatadas más ideales del mercado nacional, se utiliza ampliamente para el embotellado de refrescos, colas, bebidas con gas y otras bebidas carbonatadas.

La máquina también ofrece una amplia adaptabilidad: se puede personalizar para diferentes materiales, formas y volúmenes de botellas según los requisitos del cliente, proporcionando soluciones de producción flexibles y eficientes.

El diseño avanzado de la válvula garantiza una mínima pérdida de CO₂, niveles de llenado consistentes y una operación estable.

Soporta de 2,000 a 40,000 botellas por hora dependiendo del tipo de envase, ideal para una producción escalable.

El PLC Siemens con pantalla táctil HMI ofrece control sencillo, limpieza CIP y alertas de fallas en tiempo real.

Compatible con botellas PET, botellas de vidrio y latas, con cambios de formato rápidos.

Todas las partes en contacto están fabricadas en acero inoxidable SUS304/316 para garantizar la higiene y el cumplimiento de la seguridad alimentaria.

La estructura todo en uno ahorra espacio y mano de obra, mejorando la eficiencia de la línea.

Funciona con orientadores, etiquetadoras, envolvedoras retráctiles, impresoras y más para una solución completa.

| Modelo de producto | GQ08A | GQ10A | GQ15A | GQ20A | GQ25A |

| Capacidad | 10000 | 12000 | 24000 | 36000 | 48000 |

| Tipo de botella | Botellas multiformato de 250 ml a 2000 ml | ||||

| Tipo de bebida | Cola, soda, agua con gas, etc. | ||||